Parasitic vibrations are the bane of every speaker designer. With the push to smaller, lighter speakers with more powerful amplifiers, minimizing enclosure vibration is becoming even more critical.

Some designers measure panel vibration by gluing accelerometers onto the object under test. The mere presence of the accelerometers affects the vibration by locally adding mass and stiffness, rendering the measurements inaccurate and misleading.

Additionally, with accelerometers, there is no way to correlate the measurements, no way to “see” the direction of the wave on the surface and no way to predict the contribution to SPL. One could obtain about as much useful information by feeling the vibrations with one’s fingertips, which is what many speaker designers still do. Some designers prefer to rely solely on listening.

To combat vibration, designers add bracing, guided by trial-and-error, by simulation (FEA), or by intuition. The same fingers/ears are then used to assess whether or not improvement was made. For lack of adequate tools, bracing and vibration analysis is a highly inexact process yielding dubious benefits.

The Klippel Laser Scanning Vibrometer (SCN Module) changes all of that. Not only can we measure the vibrations, we can measure them with precision (down to nanometer resolution), we can visualize the vibrations, see the traveling waves on the surface, and we can separate out the different modes. We can even predict with accuracy the SPL contribution from the vibrating surface.

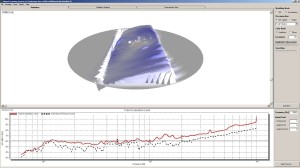

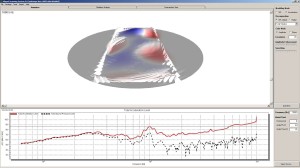

In the top image we see a very resonant enclosure. At 1000Hz, the enclosure contributes 74dB SPL! If the speakers produce 90dB SPL, then the distortion created by enclosure vibration could be audible, especially if the opposing wall is doing the same thing (it is). Luckily in this case the resonance was found in a prototype, and not in an off-tool part. Based on the information in the scan, we were able to apply bracing in the precise spot to yield the greatest benefit. The SPL contribution is now only 59dB SPL, a 15dB improvement!

Read more about vibration measurement…