NF ACOUSTIC CAMERA

REAL-TIME SOUND MAPPING OF TRANSIENT NOISES

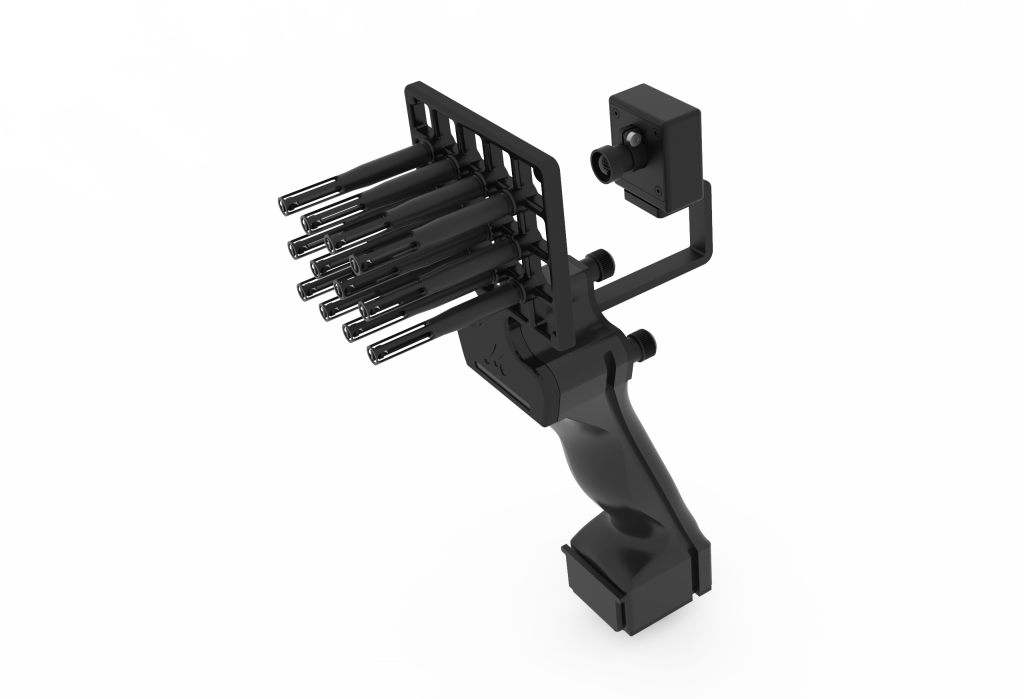

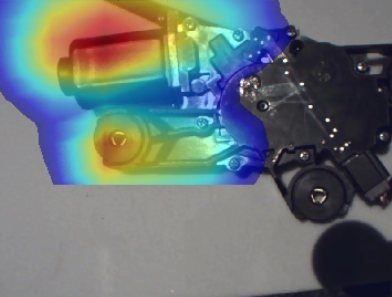

The Microflown Acoustic Camera is a flexible and versatile all-in-one box solution, which allows for real-time localization and analysis of non-stationary noises such as squeaks, rattles and clicks. All that, can be done either by a direct sound field visualization technique, or by employing acoustic holography algorithms for near-field sound reconstruction.

Sound source localization of transient and other non-stationary noises requires a simultaneous measurement with multiple sensors. The Acoustic Camera is a tool for real-time sound field visualization.

It is a perfect tool for diagnostics and localization of non-stationary sources from product development stage till end of line quality control. Thanks to the unique properties of the Microflown sensor, the localization task can be performed not only in real-time, but also in any measurement environment, and in a broad frequency range (20 Hz -10 kHz). Making the Microflown Acoustic Camera the only system capable of accurate real-time sound source localization below the barrier of 200 Hz. Furthermore, to maximize the potential of a Microflown sensor array, the acoustic camera software can be equipped with acoustic holography algorithms.

Furthermore, to maximize the potential of a Microflown sensor array, the acoustic camera software can be equipped with acoustic holography algorithms.

HOW DOES IT WORK?

The provided PU probes enable direct measurement of both sound pressure & particle velocity, as a result, the sound intensity can be obtained by taking the time averaged product of both signals. This allows for sound intensity measurements across a broad frequency range (20 Hz to 10 kHz – no spacers required). Additionally, when the size of the measured area is known, the sound powerof the object undertest can easily be calculated within the Acoustic Camera software.

There is no need to preserve a defined spacing between the probes in the array. Thus the Acoustic Camera can also be configured as a scattered array, allowing to accurately measure curved surfaces and complex geometries.

The physical properties of particle velocity and the design of the sensors make our systems less susceptible to background noise. Therefore accurate sound intensity and sound power results can be obtained in situations with a high sound pressure over sound intensity ratio (P/I index). This unique feature makes this system a superb engineering tool for troubleshooting, benchmarking, or quality control of all kinds of objects in-situ. In practice, there are many cases where anechoic conditions are not applicable, for instance in an industrial manufacturing environment, or a car interior. The Acoustic Camera is a solution which does not require any compromise when taking measurements even in acoustically challenging environments.

Find more detailed information here.