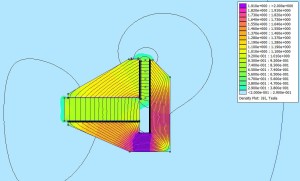

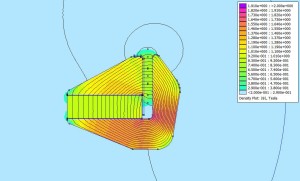

A client’s 6.5″ flat diaphragm woofer motor was also analyzed magnetically using FEM. Our objective was to increase the magnetic flux in the gap while maintaining symmetrical fringe fields, using the same Nd ring magnet and tooled basket.

This woofer motor is interesting because of the large vent hole in the center and the motor’s small size. The original design intent was to minimize the structure behind the diaphragm to reduce reflections. Also the large vent hole reduces pressure build up behind the dustcap and the moving air helps cool the motor.

Through careful analysis of FEM magnetic simulations, we found there was room for improvement. We added material to the magnetic circuit choke points and removed unnecessary material from other parts. At the same time we adhered to the size restrictions dictated by the existing woofer chassis and used the original magnet.

The result was an overall flux density increase in the gap which resulted in an increase in BL of 10%. Let us help you optimize your motor designs. Contact us to learn how.