A professional audio speaker company needed their new prototype compression driver analyzed. As the client’s R&D department did not own a Klippel laser vibrometer scanner, they turned to Warkwyn Associates for help.

Compression driver diaphragms are typically located behind a waveguide and the rear side is also blocked by the driver enclosure, making laser scanning problematic. If you can’t see the target, neither can the laser.

We fabricated a clear plastic driver enclosure to make laser scanning possible. We performed the laser scans in a vacuum in order to eliminate any modal effects caused by air.

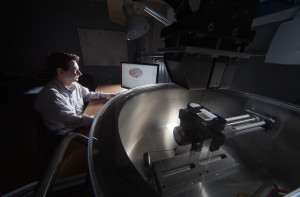

Thorough laser scanning can take many hours. We run scans overnight to minimize man-hour expenses that would normally be passed on to our clients.

We sent the scanning results to the client who used the free viewer software to analyze the results. The client was then able to make design changes to obtain better performance.